Projects

Rapid Transit Ground Support

AMIX Grout Plant (AGP) was built for client to produce extremely accurate, high quality, on-demand grout.

Location

Lake Forest, CA

Products

AGP-Hurricane

Services

Design, Engineering and Fabrication

Completion Date

Apr 2014

AGI Foundation Contractors Inc. – Port Moody, British Columbia, Canada

Project Description:

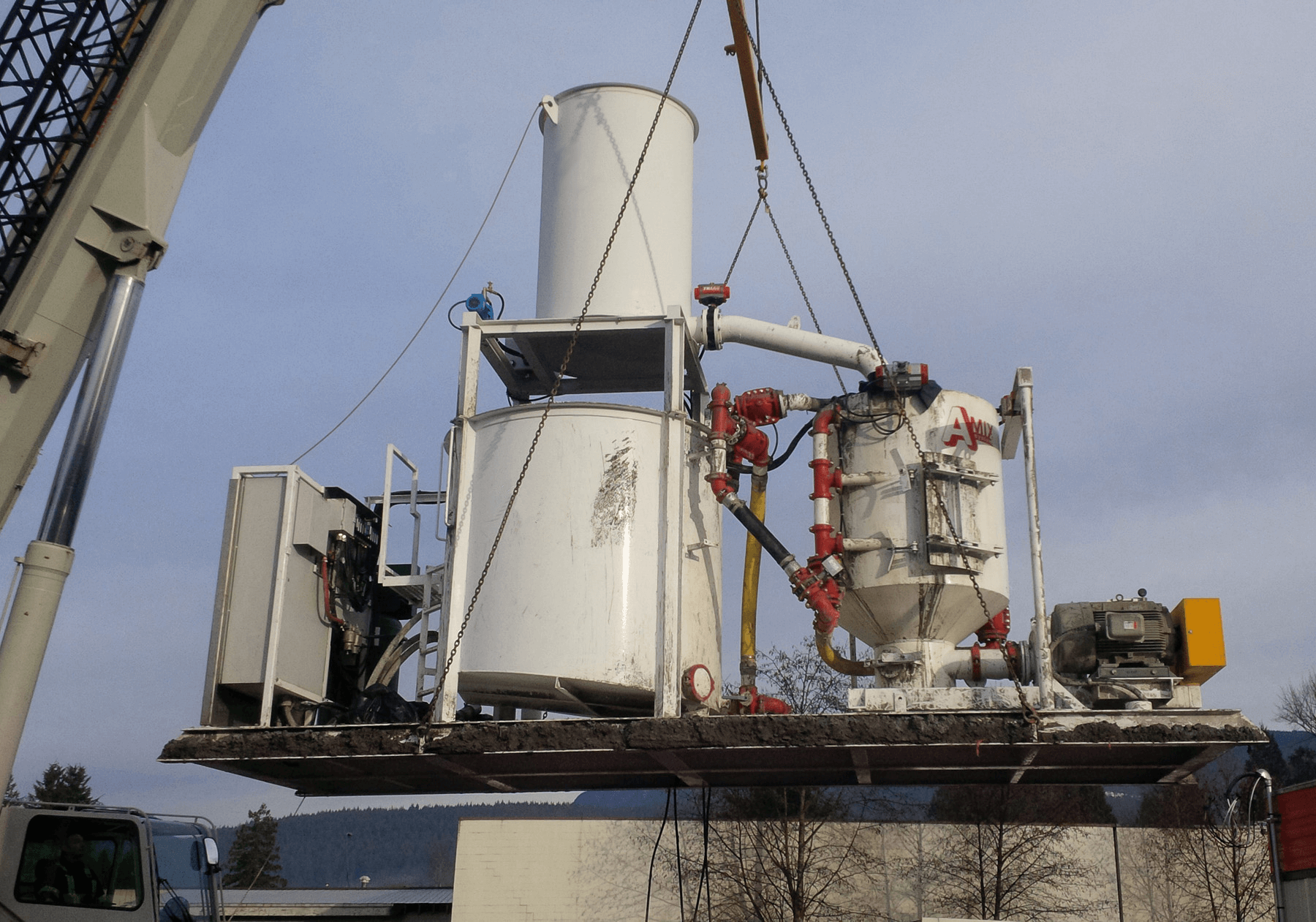

AMIX Systems was retained by AGI to design and build a high capacity grout mixing plant that could provide the quality and quantity of grout needed to keep their soil mixing operation running at maximum production.

Project Scope:

AMIX Systems was retained by AGI to design and build a high capacity grout mixing plant that could provide the quality and quantity of grout needed to keep their soil mixing operation running at maximum production.

The rapid transit line, a $1.43 billion project, is 11 km in length with elevated, at-grade, and underground sections with seven stations. AGI Foundation Contractors performed deep soil-cement mixing to stabilize soft soils along a portion of the alignment.

The Need:

A grout mixing plant was needed that could be connected to, and work seamlessly with, the soil mixing rig. Because of the length of the alignment being treated, the grout mixing plant needed to be easily transportable to move with the soil mixing rig and it needed to have a small footprint due to the narrow corridor. The plant needed to produce a highly flowable and homogeneous grout on demand.

ACM 2500 Litre High Sheer Colloidal Mixer

- High efficiency

- Fully automated

- Easy to maintain

- High quality control

- Easy to operate

- Self-cleaning

- Low waste

- Compact

“Our project required large quantities of high quality grout and we needed a grout plant that was compact, easy to set up and move and low maintenance. Amix designed a plant which contained features that we hadn’t originally envisioned but that turned out to be extremely useful, including remote controls and self-cleaning capabilities.” – Sean Callan

The Solution

AMIX provided a conceptual design and built a custom high shear colloidal mixing grout plant that included manufacturing a skid mounted grouting system. The plant was built off-site and delivered to site in an easy to set up modular design. The AMIX plant is an extremely accurate grout system producing high quality, on-demand grout. Additional features of the batch plant include it’s self-cleaning function allowing for low maintenance and little down time, as well as incorporating a remote application allowing for seamless grout flow control at the soil mixing rig.

More Accessible

AMIX Grout Plant (AGP) was simple to operate, low maintenance, compact and easy to set up and move.

More Reliable

The AMIX Grout Plant (AGP) delivered high quality grout on demand which allowed AGI to maintain a very aggressive construction schedule.

More Efficient

AMIX Grout Plant (AGP) required little or no operator intervention, minimal clean up, no waste while producing high quality grout mixes within customer specifications.

“The AMIX batch plant delivered high quality grout on demand which allowed us to maintain a very aggressive construction schedule”.

– Sean Callen, AGI

Services and Equipment Provided:

- ACM 2500 Litre High Sheer Colloidal Mixer

- Fast and slow water metering system c/w 2000 Litre water surge tank

- Control system, programmable logic

- Controller, motor controls and pneumatic systems

- Remote pump flow control

- Mounted on skid for ease of transport and setup

- Silo feed integration

The plant consistently produced high-quality grout mixes within specifications with no waste, and it required less operator intervention than other comparable plants we have in our fleet. The plant was highly mobile; it could be relocated and running again within one day using a 4-man moving crew.

Sean Callan

Construction Manager, Advanced Geo-solutions Inc.

Get a quote

If you would like to learn more about this product and receive a quote simple fill out our quote request form.

Email: sales@amixsystems.com – Phone: 1-604-746-0555

Postal Address: Suite 460 – 688 West Hastings St Vancvouver, BC V6B 1P1