The challenges are real. You know that selecting the right colloidal grout mixer for your project is key. Did you know, that not all colloidal grout mixers are the same?

What stands out in our colloidal mixer is that the technology is based on true colloidal mill shearing. The colloidal mill shears the cement particles. Competitive units use a centrifugal pump to simulate shearing, it’s not the same. Units that simulate shearing only serve as a recirculation pump and won’t have the high-shear mixing qualities.

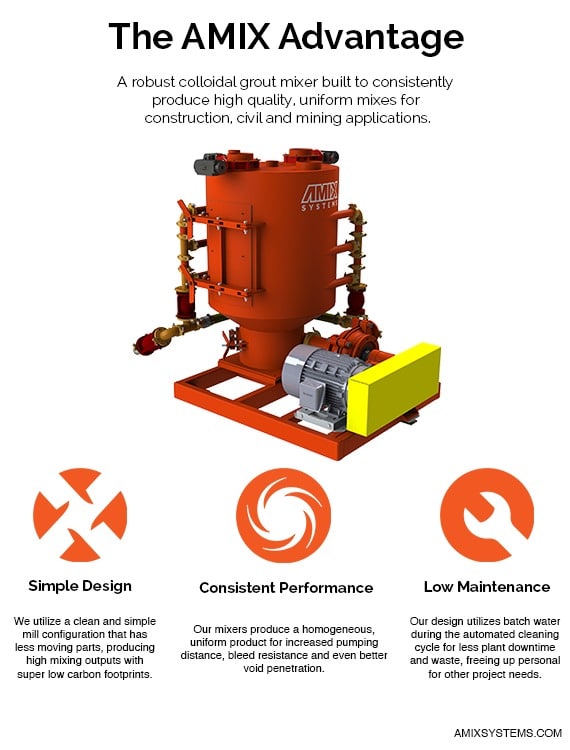

Colloidal Grout Mixer

A colloidal mill is a machine that is used to reduce the particle size of a solid in suspension in a liquid, or to reduce the droplet size of a liquid suspended in another liquid. Colloidal mills work on the rotor-stator principle: a rotor turns at high speeds (2,000 – 18,000 RPM[1]). The resulting high levels of hydraulic shear applied to the process liquid disrupt structures in the fluid. Colloidal mills are frequently used to increase the stability of suspensions and emulsions., but can also be used to reduce the particle size of solids in suspensions[1] Higher shear rates lead to smaller droplets, down to approximately 1 µm[2] which are more resistant to emulsion separation. via Wikipedia

AMIX Systems‘ colloidal mixer utilizes a clean and simple colloidal mill configuration with less moving parts, and produce high outputs while maintaining a low carbon footprint.

A high-speed rotor (discar) is housed inside the colloidal mill. Between the discar and the walls is a minimal clearance. This is where the high turbulence and shearing breaks down clusters of dry cement particles (agglomerates).

The colloidal mill may act as a centrifugal pump and discharge slurry into an agitation tank and/or other desired location. The mill has the potential to increase efficiency as a pump giving it a higher-pressure capacity. In trade off this will reduce the mills efficiency as a mixer. Lower pump efficiency requires higher energy input. Our grout mixing and pumping equipment is built application specific.

The Amix Colloidal Mixer (ACM) is designed to specifically allow for easy access for set-up and maintenance. Competitors, when using a centrifugal pump generally feature small inlet connections causing restrictions and potential cavitation problems with heavier mixes.

Superior mixing is created via the discharge velocity in combo with the inlets on the mixing vessel. This creates a high velocity vortex. Other colloidal mixers on the market routinely need the addition of a paddle-style mixer to produce such a mix worthy vortex. Contact us and we will be happy to share specifications and technical details with you