Book a discovery call with Ben MacDonald to learn how Amix Systems can transform your next project.

Getting the Lowdown on Grout Mixing Plants

How does heavy duty grout mixing work?

Grout mixing systems are the unsung heroes in construction, mining, and civil engineering. They whip up and pump out grout—a blend of cement, water, and other goodies. This magical mix fills gaps, beefs up structures, and keeps soil in check.

These plants come in all shapes and sizes, handling everything from cementitious grouts to shotcrete. The aim? A smooth, top-notch mix that nails your project’s needs. Whether you’re batching or going continuous, these plants keep things running like a well-oiled machine.

Why High Shear Mixing Plants Rock

High shear mixing plants, like the ones from AMIX Systems, bring some serious game to grout applications. Here’s why they’re the MVPs:

- Efficiency: These mixers run at full throttle, cutting downtime and cranking up productivity. AMIX Systems’ modular design makes them a breeze to use and scale.

- Automated and Self-Cleaning: Say goodbye to manual labor and contamination risks. These systems clean themselves and automate the mixing process.

- High Output: The AGP Hurricane and Cyclone series are your go-to for high and medium output needs. Customizable to fit your project like a glove.

- Eco-Friendly: These plants keep it green with a low carbon footprint while still delivering the goods (AMIX Systems).

- Durability: Built tough with fewer moving parts, these plants are in it for the long haul. Perfect for heavy-duty mixing.

Here’s a quick rundown of why high shear mixing plants are the bee’s knees:

| Benefit | What It Means |

|---|---|

| Efficiency | Full capacity, less downtime |

| Automated and Self-Cleaning | Easy peasy, no contamination |

| High Output | Fits high and medium output needs |

| Eco-Friendly | Low carbon footprint |

| Durability | Tough and reliable |

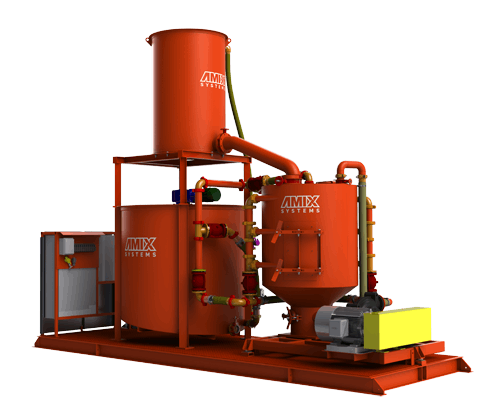

AMIX Systems Grout Plants

Looking for top-notch grout mixing solutions? AMIX Systems Grout Plants are your go-to. With their smart design and powerful features, these plants are perfect for construction, mining, and civil engineering projects.

Smart Modular Design

AMIX Systems Grout Plants (AGP) use a modular design that makes them easy to use and expand. This means fewer moving parts and a simpler setup, so you can run them efficiently even when they’re working hard. Plus, you can customize them to fit your project needs.

Key features include:

- Ease of Use: Simple setup and user-friendly interface make them accessible for everyone.

- Scalability: Easily expand or reconfigure to fit different project sizes.

- Low Maintenance: Fewer moving parts mean less wear and tear, so they last longer and need less upkeep.

| Feature | Benefit |

|---|---|

| Ease of Use | Simple setup, user-friendly |

| Scalability | Easily expandable |

| Low Maintenance | Less wear and tear, longer lifespan |

Versatile Applications

AMIX Systems Grout Plants can handle a variety of tasks, from high-output to lower-output operations. They’re great for construction, mining, and civil engineering.

AGP Hurricane Line

The AGP Hurricane line is built for high-output jobs. You can customize these plants for almost any task, making it easy to scale your operations (AMIX Systems). They also have a low carbon footprint, so they’re good for the environment.

AGP Typhoon Line

The AGP Typhoon line is perfect for lower output tasks. You can get these plants in manual, semi-automated, or fully-automated setups (AMIX Systems). Choose the level of automation that fits your project best.

AGP Cyclone Line

For medium output jobs, the AGP Cyclone line is a solid choice. These plants offer high outputs and a low carbon footprint, making them environmentally friendly.

| Line | Output Level | Customization | Environmental Impact |

|---|---|---|---|

| AGP Hurricane | High | High | Low carbon footprint |

| AGP Typhoon | Low | Manual to fully automated | Low carbon footprint |

| AGP Cyclone | Medium | Medium | Low carbon footprint |

AMIX Systems Grout Plants are reliable and versatile for all your grout mixing needs.

AMIX Systems Mixing Plant Varieties

AMIX Systems has a range of mixing plants to fit the needs of engineers in construction, mining, and civil works. Let’s break down the AGP Hurricane Line, AGP Typhoon Line, and ACM Technology in AGP Cyclone Plants.

AGP Hurricane Line Features

The AGP Hurricane line is built for high-output jobs and can be tweaked to fit almost any project (AMIX Systems). These grout plants are top-notch, eco-friendly, and self-cleaning. They can run non-stop, need little maintenance, and have low wear and tear.

| Feature | Description |

|---|---|

| Operational Availability | 24/7 |

| Maintenance | Low |

| Wear Component Consumption | Low |

| Carbon Footprint | Low |

| Customization | High |

Perfect for projects that need continuous, high-output performance.

AGP Typhoon Line Overview

The AGP Typhoon line is great for medium-output jobs, balancing performance and efficiency. These grout plants handle various grouting needs with minimal environmental impact. They’re self-cleaning, can run 24/7, and are known for their high availability and low wear and tear.

| Feature | Description |

|---|---|

| Operational Availability | 24/7 |

| Maintenance | Low |

| Wear Component Consumption | Low |

| Carbon Footprint | Low |

| Customization | Medium |

Ideal for projects needing reliable and efficient grout mixing.

ACM Technology in AGP Cyclone Plants

The AGP Cyclone line uses ACM (Advanced Colloidal Mixing) technology, making it a solid choice for both high and medium-output jobs. These plants have high-performance mills with replaceable liners, impellers, and mechanical seals made of high chrome, ensuring durability even with abrasive materials like sanded mixes.

| Feature | Description |

|---|---|

| Mill Performance | High |

| Durability | High |

| Maintenance | Easy |

| Material Compatibility | High abrasives (e.g., sanded mixes) |

ACM technology in AGP Cyclone plants ensures efficient operation with minimal downtime, making it perfect for tough projects. For more details, visit our section on grout machinery.

By knowing the features and capabilities of each AMIX Systems mixing plant, you can pick the best high shear plant for your project. Whether it’s the high-output Hurricane line, the balanced Typhoon line, or the durable Cyclone line with ACM technology, AMIX Systems has reliable solutions for all your grout mixing needs.

Features of AMIX Colloidal Mixer

The AMIX Colloidal Mixer (ACM) is a top-notch tool for grout mixing in construction, mining, and civil works. Let’s break down its design, functionality, performance, and maintenance needs.

Design and Functionality

The ACM is built tough to ensure consistent, high-quality mixes for various jobs. Its high-performance mills are made to last, featuring durable parts like replaceable liners, impellers, and mechanical seals crafted from high chrome. This makes the ACM reliable and easy to maintain, even when dealing with abrasive materials like sanded mixes.

Key design features include:

- Self-Cleaning Mechanism: The ACM cleans itself using batch water, cutting down on downtime and waste.

- Scalable and Off-the-Shelf: This mixer can work solo or as part of a complete grout mixing and pumping system, freeing up your team for other tasks.

- Fewer Moving Parts: With fewer moving parts, the ACM is more efficient and easier to maintain.

Performance and Maintenance Requirements

The AMIX Colloidal Mixer is designed for top performance, running at or near full capacity. This means your projects get done faster without sacrificing quality.

Performance highlights include:

- High-Efficiency Mills: The ACM’s mills deliver consistent, high-quality mixes, crucial for construction and equipment grouting.

- Durability: High chrome components ensure the ACM can handle tough materials, offering long-term durability with minimal wear and tear.

Maintenance is straightforward and minimal:

| Component | Maintenance Frequency | Notes |

|---|---|---|

| Liners | Replace as needed | High chrome liners last longer |

| Impellers | Inspect regularly | Easy to replace for continuous performance |

| Mechanical Seals | Check periodically | Durable seals reduce leakage and extend life |

By understanding the design, functionality, performance, and maintenance needs of the AMIX Colloidal Mixer, you can make smart choices for your project’s grout mixing pumps and batch mixer needs.

The Benefits of Choosing an AMIX High Shear Plant

When it comes to high-performance grout mixing applications, an AMIX high shear plant offers unparalleled efficiency and reliability. Here are some key benefits of selecting an AMIX high shear plant for your project:

- Consistent, High-Quality Mixes: AMIX high shear plants feature advanced colloidal mixing technology that ensures homogeneous, uniform grout mixes. This results in increased pumping distance, bleed resistance, and void penetration for optimal performance.

- Reduced Downtime and Maintenance: The self-cleaning design of AMIX high shear plants uses batch water to minimize downtime, clean-up, and maintenance requirements. This allows the plants to operate at or near 100% capacity 24/7, maximizing productivity.

- Scalability and Customization: AMIX high shear plants are available in a range of sizes and configurations to suit various project needs. From the high-output AGP Hurricane line to the versatile AGP Typhoon and Cyclone series, these plants can be easily customized and scaled to meet specific requirements.

- Eco-Friendly Operation: With a focus on reducing waste and maintaining a low carbon footprint, AMIX high shear plants promote environmentally sustainable practices in grout mixing applications.

- Proven Performance: AMIX high shear plants have a proven track record of success in challenging projects across the mining, tunneling, and heavy civil construction industries. From the Seymour-Capilano Twin Tunnels Filtration Project to the Deep Soil Mixing Colloidal Grout Plant, AMIX Systems has delivered tailored solutions that exceed client expectations.

- Expert Support: AMIX Systems offers comprehensive support services, including consulting, design, fabrication, control systems, automation, plant retrofitting, commissioning, training, and maintenance. Their experienced team works closely with clients to ensure optimal performance and success throughout the project lifecycle.

Investing in an AMIX high shear plant not only guarantees efficient and reliable grout mixing but also provides access to industry-leading expertise and support. Whether you’re working on a tunneling project, deep soil mixing application, or any other grouting task, an AMIX high shear plant is a smart choice for achieving exceptional results.

Final Thoughts

In the world of high-performance grout mixing applications, an AMIX high shear plant stands out as the ultimate solution for efficiency, reliability, and customization. With advanced colloidal mixing technology, self-cleaning design, and scalable options, AMIX Systems offers a range of high shear plants tailored to meet the unique needs of mining, tunneling, and heavy civil construction projects.

By choosing an AMIX high shear plant, you can benefit from consistent, high-quality grout mixes, reduced downtime and maintenance, eco-friendly operation, and proven performance backed by expert support. Whether you opt for the high-output AGP Hurricane line, the versatile AGP Typhoon series, or the durable AGP Cyclone plants with ACM technology, you can trust AMIX Systems to deliver exceptional results.

Don’t settle for less when it comes to your grout mixing needs. Invest in an AMIX high shear plant and experience the difference in efficiency, reliability, and performance. Contact the knowledgeable staff at AMIX Systems today to discuss your project requirements and learn more about how their high shear plants can benefit your operations.

Book A Discovery Call

Empower your projects with efficient mixing solutions that enable scalable and consistent results for even the largest tasks. Book a discovery call with Ben MacDonald to discuss how we can add value to your project:

Email: info@amixsystems.com – Phone: 1-604-746-0555

Postal Address: Suite 460 – 688 West Hastings St, Vancvouver, BC. V6B 1P1