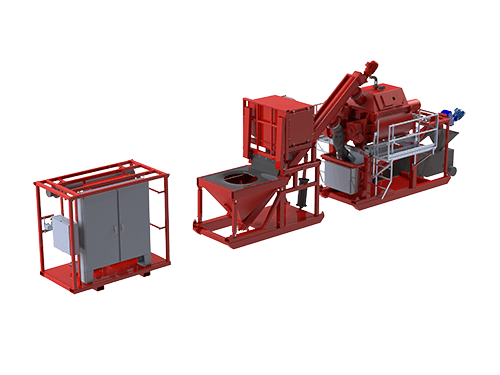

Plant Overview Wet & Dry Mix Modes:

The shotcrete system will be capable of mixing and spraying both wet and dry applications. The bulk bag unloader mixer feed screw will have two discharge points. One to feed the shotcrete to the mixer at the end and one slightly lower down the screw to feed a chute that will bypass the mixer into the shotcrete transfer screw hopper. Water trim (adjustable water add) is added to the shotcrete transfer screw and becomes a pre-dampener while in dry mode. This is to moisten the shotcrete material to reduce dust generation. The shotcrete plants typical mode of operation will be wet mix, which is efficient and best performing out of the two modes. Dry mode will be used when only a short amount of shotcrete will be required in the day. Dry mode has the advantage of not having much clean up after production. Mode selection will be done by using a selector switch on the control panel. In both wet & dry modes prepackaged shotcrete will be in bulk bags. Using a monorail, forklift or other kind of lifting / feeding device by others will feed bulk bags into hopper. The batch mixer will be fully automated to insure and maintain shotcrete quality and consistency. Shotcrete discharge from mixer to shotcrete pot screw conveyor will be automated. Shotcrete feed into shotcrete pot from pot screw conveyor will be automated.