We Build Grout Mixing Plants that Perform

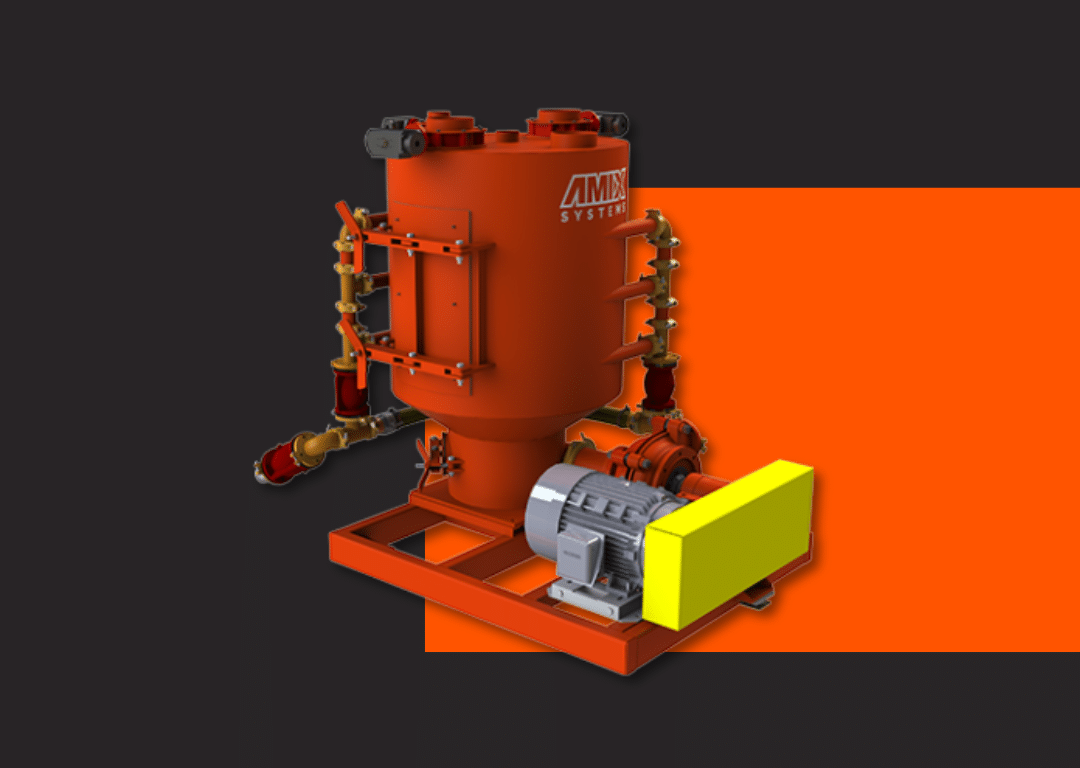

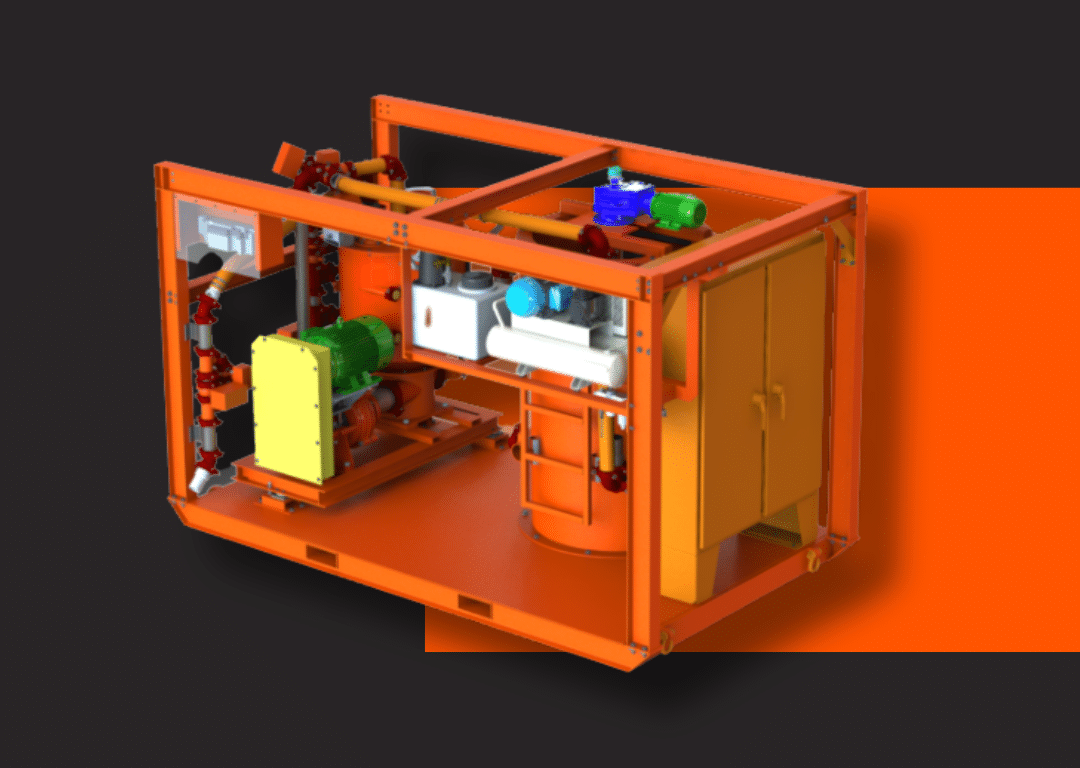

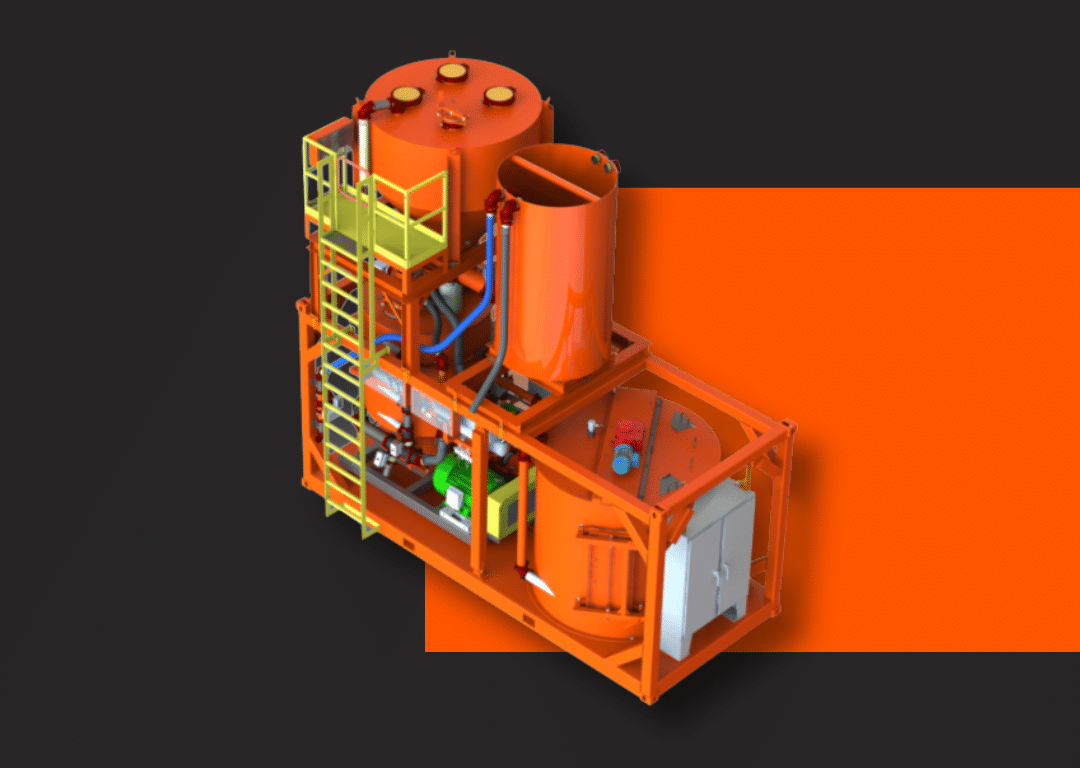

Amix Grout Plants (AGP) are advanced mixing and pumping systems designed for high output and low environmental impact. Built on modular design principles, they offer easy operation, scalability, and reliable performance.

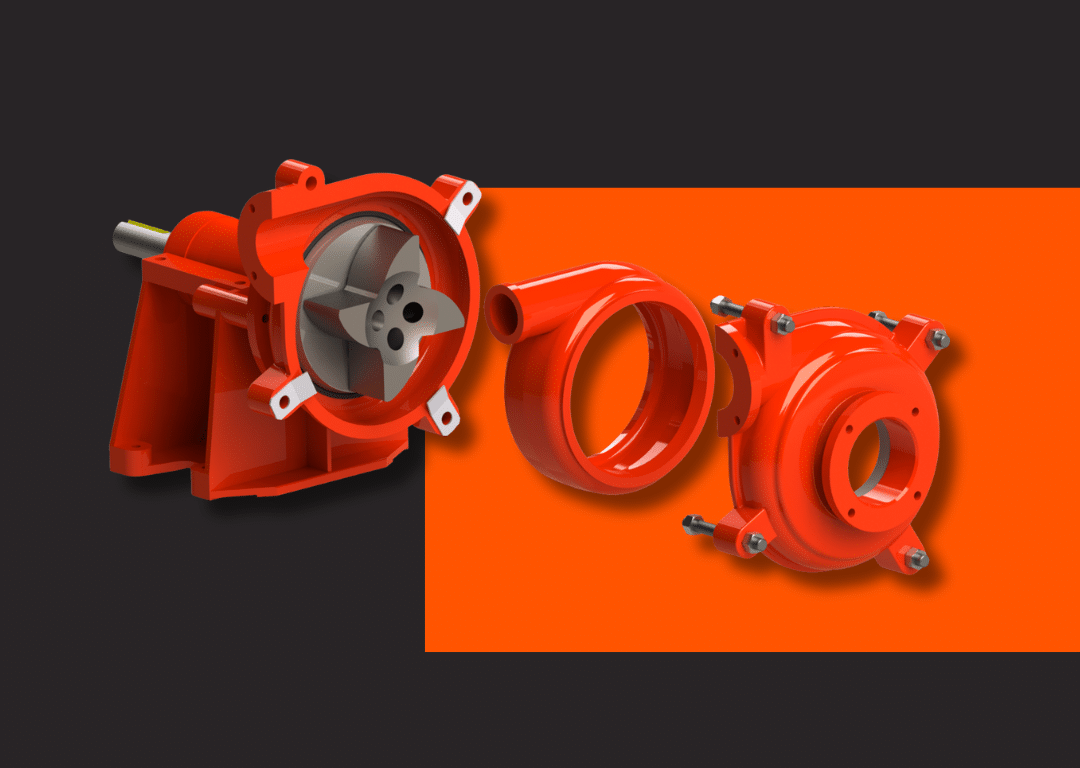

With clean, simplified mill configurations and fewer moving parts, AGP systems ensure consistent operation at or near full capacity—minimizing maintenance while maximizing efficiency.