Book a discovery call with Ben MacDonald to learn how Amix Systems can transform your next project.

Grout Pumping Equipment for Mining and Construction Projects

Grout Pumping Solutions Overview

AMIX Systems’ Top-Notch Slurry Pumps

Hey there, engineers! If you’re knee-deep in construction, mining, or civil works, AMIX Systems has your back with a lineup of slurry pumps built to tackle the toughest, grittiest jobs. These bad boys are all about high efficiency, long life, and easy-peasy maintenance.

| Feature | Description |

|---|---|

| Durability | Built for the rough and tough world of metallurgical, mining, and industrial work |

| Efficiency | Keeps things running smoothly without guzzling energy |

| Maintenance | Simple upkeep means less downtime and more action |

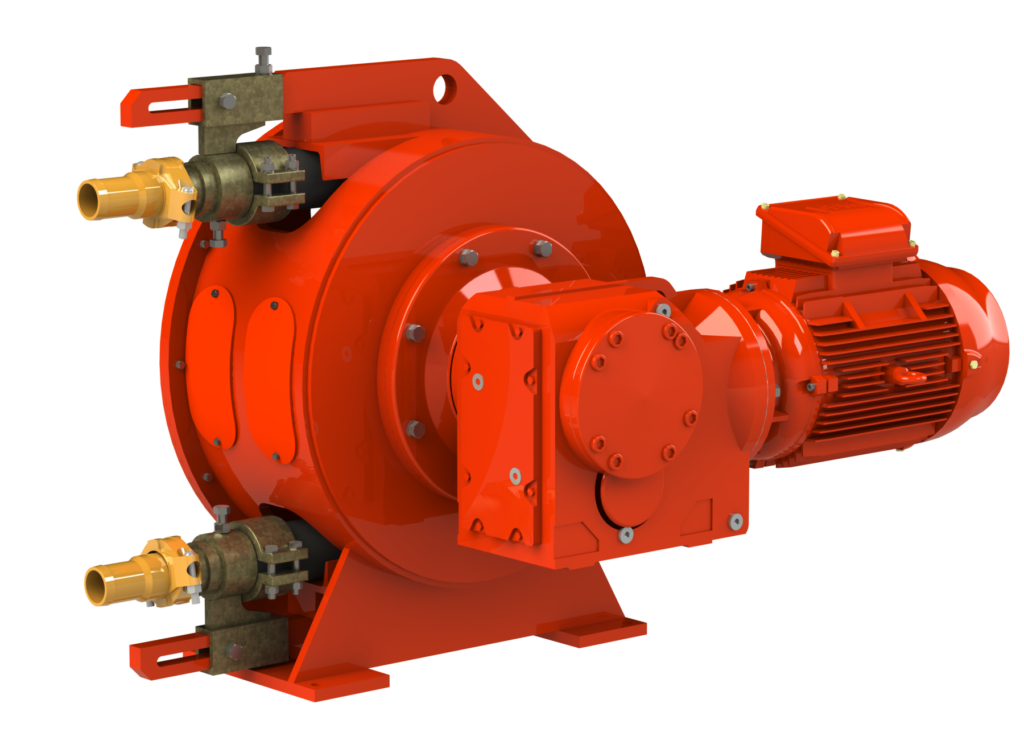

Peristaltic Pump for Tough Jobs

Meet the AMIX Systems Peristaltic Pump (APP), your new best friend for handling the nastiest, thickest, and most abrasive stuff out there. Perfect for high-viscosity, high-density products, this pump laughs in the face of corrosive acids, gaseous liquids, sand/cement, and mortar. Whether you’re in construction, civil, or mining, this pump’s got you covered (AMIX Systems).

| Feature | Description |

|---|---|

| Versatility | Pumps just about anything, from thick goop to gritty sludge |

| Resistance | Stands up to the harshest, most abrasive materials |

| Applications | A must-have for construction, civil, and mining projects |

The peristaltic pump’s knack for handling all sorts of materials makes it a game-changer for anyone looking to up their equipment grouting and construction grouting game.

Grout Pumping Equipment for Efficient Project Completion

Efficient grout pumping is essential for the success of various construction projects, including ground improvement, earth retention, and deep foundations. AMIX Systems offers a wide range of grout pumping equipment designed to meet the specific needs of each project.

Peristaltic Pumps for Abrasive Materials

AMIX Systems Peristaltic Pumps (APP) are ideal for grout pumping applications involving highly abrasive materials, such as sand/cement and mortar mixes. These pumps can handle high-viscosity and high-density products, making them perfect for demanding construction environments.

Key features of the APP include:

- Ability to pump corrosive acids and gaseous liquids

- High pressure capability up to 3 MPa (435 psi)

- Precise metering with +/- 1% accuracy

- Easy maintenance with replaceable hose tubes

HDC Slurry Pumps for Reliable Grout Pumping

For grout pumping projects requiring reliable and durable equipment, AMIX Systems offers HDC Slurry Pumps. These heavy-duty slurry pumps are designed to handle a variety of abrasive and corrosive slurries, making them suitable for a wide range of applications.

HDC Slurry Pumps feature:

- High capacity ranging from 400 m3/hr to 5040 m3/hr

- Maximum pressure of 20.7 bar (300 psi)

- Wear-resistant pump parts made from ASTM A532 Grade 3A high chrome material

- Easy maintenance with replaceable liners, impellers, and mechanical seals

By utilizing the right grout pumping equipment, construction professionals can ensure efficient project completion and minimize downtime. AMIX Systems’ peristaltic pumps and HDC slurry pumps provide reliable solutions for various grout pumping applications.

Advanced Grout Mixing Plants

AGP Hurricane Series Features

The AGP Hurricane Series from AMIX Systems is a game-changer in grout pumping. Built for heavy-duty tasks, these grout plants are perfect for construction and mining jobs like cement grouting, jet grouting, soil mixing, and annulus backfill.

Here’s what makes the AGP Hurricane Series stand out:

- Always On: These machines can run 24/7, keeping your projects moving without a hitch.

- Self-Cleaning: Less time cleaning means more time working. These plants clean themselves, cutting down on maintenance.

- Durable Parts: Built to last, these plants use fewer wear parts, saving you money on replacements.

- Customizable: Whatever your project needs, these plants can be adjusted to fit.

- Eco-Friendly: High output with a low carbon footprint. Good for your project, good for the planet.

| Feature | Benefit |

|---|---|

| Always On | Keeps projects moving |

| Self-Cleaning | Less downtime |

| Durable Parts | Saves on costs |

| Customizable | Fits any project |

| Eco-Friendly | Low carbon footprint |

Modular Design for Scalability

The AGP Hurricane Series is all about flexibility and ease of use. Its modular design means you can scale up or down as needed, making it perfect for any project size.

- User-Friendly: Simple setup with fewer moving parts means it runs smoothly with minimal fuss.

- Scalable: Add or remove components as your project demands.

- Versatile: Ideal for a range of tasks like micro tunneling lubrication, bentonite mixing, micropile grouting, and cemented rockfill (CRF) (AMIX Systems).

| Modular Design Feature | Advantage |

|---|---|

| User-Friendly | Smooth operation |

| Scalable | Grows with your needs |

| Versatile | Handles multiple tasks |

This modular approach not only boosts efficiency but also ensures your investment is ready for the future.

The AGP Hurricane Series and its modular design reflect AMIX Systems’ dedication to top-notch grout mixing plants. For more details and to explore other advanced solutions, visit our pages on construction grout mixers and grout mixing pumps.

Colloidal Grout Mixers

Self-Cleaning Colloidal Mixer Design

The Amix Colloidal Mixer (ACM) is a top-notch solution for grout mixing and pumping in civil and mining projects. One of its coolest features is the self-cleaning design, which uses batch water for cleaning. This smart feature cuts down on downtime and waste, keeping your plant running smoothly and efficiently.

The self-cleaning mechanism not only makes your equipment last longer but also reduces the need for maintenance. This means more bang for your buck and less time spent on repairs, which is a big deal for large construction and mining operations.

| Feature | Benefit |

|---|---|

| Self-Cleaning Design | Less downtime and waste |

| Batch Water Cleaning Cycle | Keeps performance high |

| High-Performance Centrifugal Pumps | Reliable and durable |

For more details on this technology, check out our grout mixing pumps section.

Versatile Applications in Construction

Amix Systems’ colloidal grout mixers are built to handle a variety of construction needs. These mixers are perfect for tasks like Jet Grouting, Soil Mixing, Tunnel Boring (TBM), Two Component Annulus Backfill Grouting, Permeation Grouting, Bentonite Mixing, Paste Backfill, and Cemented Rockfill (CRF) (AMIX Systems).

This versatility makes the ACM a must-have for engineers working on different projects. Whether you’re into construction grouting or backfill grouting, the ACM has got you covered. The high-performance centrifugal slurry pumps with 29% chrome replaceable liners, impellers (discar’s), and high-performance mechanical seals ensure reliability and easy maintenance (AMIX Systems).

| Application | Example |

|---|---|

| Jet Grouting | Soil stabilization |

| Tunnel Boring (TBM) | Annulus Backfill Grouting |

| Permeation Grouting | Ground improvement |

| Bentonite Mixing | Tunneling and drilling support |

| Cemented Rockfill (CRF) Plants | Mining backfill operations |

These mixers can work solo or as part of a complete grout mixing and pumping system, offering both flexibility and efficiency. They are also automated, freeing up your team to focus on other important tasks without having to constantly check on the equipment.

Grout Pumping Accessories for Optimized Performance

To optimize grout pumping performance and efficiency, AMIX Systems offers a range of accessories designed to complement their colloidal grout mixers and pumps. These accessories help streamline the grout pumping process and minimize downtime.

Agitated Tanks for Consistent Mixing

AMIX Systems’ Agitated Tanks (AAT) are reliable, long-lasting, and built in various sizes for easy integration or standalone applications. Key features include:

- Point/continuous level indication

- Water flush systems

- Construction in mild or stainless steel

- Variable RPM (20-150) with adjustable speed drive

- Bottom, side, and multiple discharge options

- Heavy-duty dual bearing gearboxes for reduced wear part replacement

- Optional inspection door for easy maintenance and cleaning

Silos, Hoppers, and Feed Systems for Efficient Material Handling

AMIX Systems designs and builds vertical and horizontal bulk storage silos, bins, hoppers, conveyors, micro-ingredient feeders, and bulk bag unloaders to suit specific applications and site conditions. Features include:

- Standard or custom configurations

- Vertical silos with access ladders, cagers, and roof rails

- Horizontal silos mounted on load cells for product inventory

- Screw feeders for product discharge

- Heavy-duty 100% welded steel shells and matched understructures

- Low-pressure aeration manifolds

- HD butterfly discharge valves

- Rooftop pulse-jet dust collectors matched to pneumatic fill rates

Modular Containers for Enhanced Protection and Mobility

AMIX Systems offers containerized or skid-mounted solutions for enhanced protection, site security, and easy transportation. These modular containers are designed to suit equipment installation and feature:

- 20′ or 40′ (L) x (W) x 8′ (H) 9′-6″ new steel container

- 3/16″ floor plating stitched and sealed around the perimeter

- Standard steel insulated man door

- Base plates/mounting pads for all equipment

- Water, grout, and other service inlets/outlets fit and welded through the container walls and ceiling

- All equipment and components related to the grout plant mounted and wired

- LED interior lighting with water-tight enclosures

By utilizing these accessories alongside AMIX Systems’ grout pumping equipment, construction professionals can optimize their grout pumping processes, reduce waste, and improve overall project efficiency.

Efficiency and Productivity

Automated Solutions for Better Productivity

AMIX Systems’ automated colloidal grout mixers are built to boost productivity on construction, mining, and civil works sites. These mixers can work solo or as part of a complete grout mixing and pumping system, offering flexibility and efficiency. The automation lets your team focus on other important tasks, cutting out the need for constant monitoring.

Key features that improve productivity include:

- Self-Cleaning Mechanism: The ACM colloidal grout mixers clean themselves, reducing downtime for maintenance and keeping things running smoothly.

- 24/7 Operation: The Hurricane Series mixers can run non-stop, offering the highest operational availability with minimal wear and tear.

- User-Friendly Interface: These automated systems are easy to use, freeing up your team for other tasks and cutting down on training time.

| Feature | Benefit |

|---|---|

| Self-Cleaning Mechanism | Less downtime and maintenance |

| 24/7 Operation | Maximum operational availability |

| User-Friendly Interface | Less need for constant supervision |

Reliability and Durability in Grout Pumping Equipment

Reliability and durability are crucial aspects of any grout pumping equipment, especially in challenging construction environments. AMIX Systems’ grout pumps are designed to withstand continuous use while maintaining high performance and efficiency.

- Robust Construction: AMIX Systems Peristaltic Pumps (APP) feature a heavy-duty design capable of handling aggressive, high-viscosity, and high-density products, making them ideal for abrasive slurry, corrosive acids, gaseous liquids, sand/cement, and mortar applications.

- High-Quality Components: The HDC Slurry Pumps are equipped with wear-resistant pump parts made from ASTM A532 Grade 3A high chrome material, such as impellers, volute liners, throatbush, FLP inserts, and cover plates, ensuring long service life and easy maintenance.

- Low Maintenance: The grout pumps are designed to minimize downtime and maintenance requirements. The APP features replaceable hose tubes as the only wear item, while the HDC Slurry Pumps have replaceable liners, impellers, and mechanical seals for easy upkeep.

| Component | Benefit |

|---|---|

| Heavy-Duty Construction | Withstands harsh environments and abrasive materials |

| High-Quality Wear-Resistant Parts | Prolongs equipment lifespan and reduces maintenance |

| Low Maintenance Design | Minimizes downtime and increases operational efficiency |

Investing in reliable and durable grout pumping equipment not only improves efficiency but also ensures long-term productivity in your construction projects. Discover more about AMIX Systems’ grout pumps and how they can benefit your operations.

Final Thoughts on Grout Pumping Solutions

Grout pumping is a critical aspect of many construction, mining, and civil engineering projects. By choosing the right equipment and accessories, you can optimize your grout pumping processes, improve efficiency, and minimize downtime.

AMIX Systems offers a comprehensive range of grout pumping solutions, including peristaltic pumps, HDC slurry pumps, colloidal grout mixers, and various accessories such as agitated tanks, silos, hoppers, feed systems, and modular containers. These products are designed to handle the toughest challenges in grout pumping applications, ensuring reliable performance and long-lasting durability.

With automated solutions and user-friendly interfaces, AMIX Systems’ grout pumping equipment allows your team to focus on other important tasks while maintaining consistent mix quality and high output. The self-cleaning mechanisms and low maintenance requirements further contribute to increased productivity and reduced operational costs.

Book A Discovery Call

Empower your projects with efficient mixing solutions that enable scalable and consistent results for even the largest tasks. Book a discovery call with Ben MacDonald to discuss how we can add value to your project:

Email: info@amixsystems.com – Phone: 1-604-746-0555

Postal Address: 8215 Dallas Dr, Kamloops, BC V2C 6X2